JAM PROCESSING UNIT

A Jam Processing Unit is a specialized facility focused on converting fresh fruits into delectable jams. Key steps involve receiving, washing, and peeling fruits, followed by cutting, cooking, and adding sugar and pectin for thickness. Boiling, skimming, flavouring, and pasteurization contribute to the final jam's taste, texture, and preservation. The cooled jam is carefully filled into jars, sealed, and labelled before packaging.

JAM PROCESSING UNIT

Fruit Jam:

Fruit jam is a sweet spread made by cooking fruit with sugar to create a thick, flavorful mixture. The fruit is typically crushed or chopped, and then it's combined with sugar and sometimes pectin to achieve the desired consistency. Common fruits used for jam include strawberries, raspberries, apricots, peaches, and more.

Fruit Jam Processing:

Making fruit jam involves a straightforward but careful process to ensure a delicious and safe product. Here's a general overview of the steps involved in fruit jam processing:

- Prepare the Fruit: Wash and chop the fruit into small, uniform pieces. Crush or mash the fruit to release juices.

- Cooking: Combine fruit and sugar in the pot. If using pectin, add it according to the package instructions. Bring the mixture to a boil, stirring frequently.

- Fill Jars: The boiled Jam is filled in sterilized jars.

- Seal the Jars: Sterilized lids are used to close the jars.

- Cooling: Allow jars to cool on a clean towel or cooling rack.

- Labeling and Storing: Label the jars with the date and type of jam. Store in a cool, dark place.

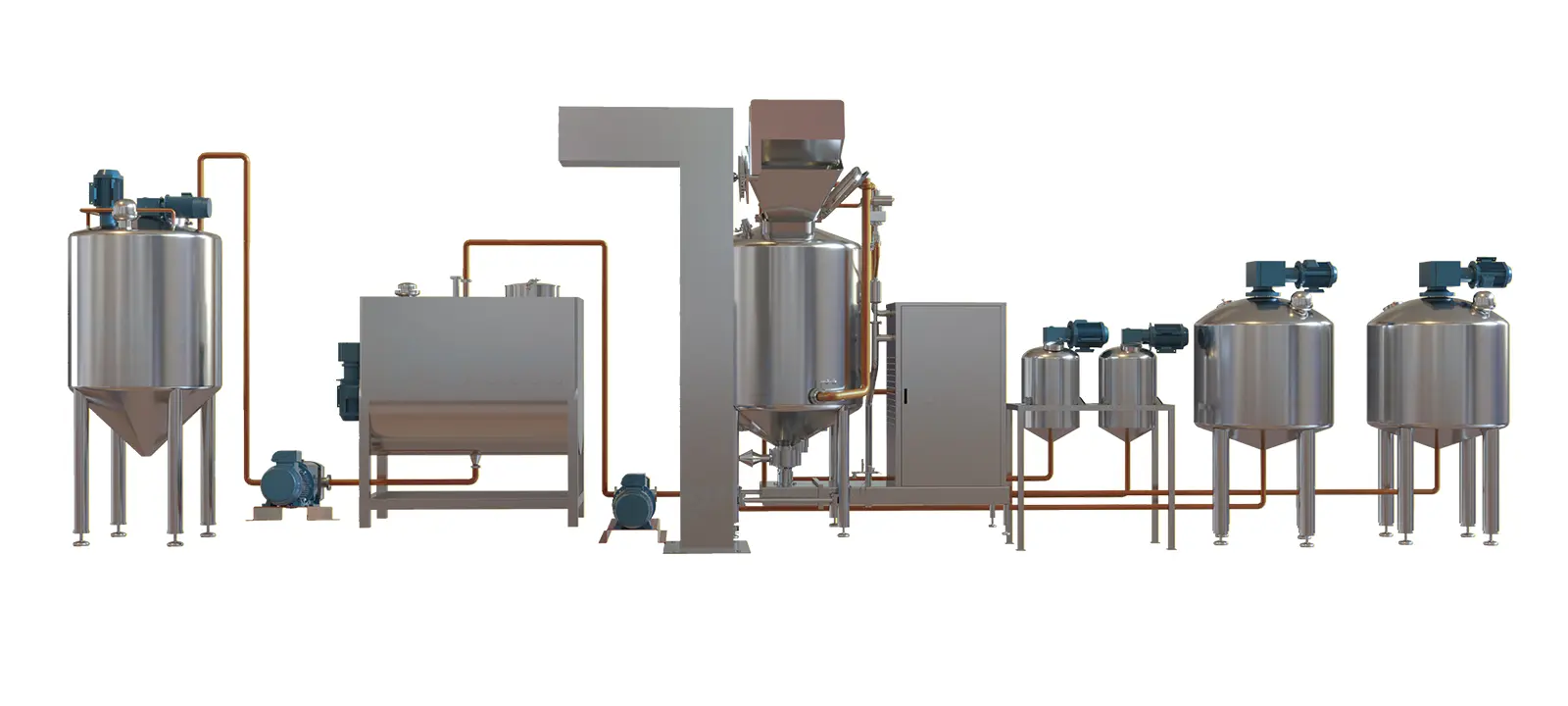

Fruit Jam Processing Solutions:

We, at We Smart Engineering, stand as a global leader in providing cutting-edge and high-quality Jam Processing equipment tailored to meet the dynamic requirements of the Jam Processing industry. Our unwavering dedication to excellence has positioned us as a reliable partner for Jam processors across the globe. Processing equipment for making fruit jam can vary depending on the scale of production, here are some of equipment used in the process

- Fruit Washing and Sorting Equipment

- Fruit Washer: Removes dirt and impurities from the fruits.

- Fruit Sorter: Sorts fruits based on size and quality.

- Fruit Cutting and Crushing Equipment

- Fruit Cutter/Chopper: Cuts or chops the fruits into smaller pieces.

- Fruit Crusher: Crushes the fruit to extract juices and pulp.

- Cooking and Mixing Equipment

- Cooking Kettle: Heats the fruit mixture along with sugar and pectin to achieve the desired consistency.

- Mixing Tank: Combines the fruit, sugar, and pectin evenly.

- Pectin Mixing and Dosing System

- Pectin Dissolver: Mixes pectin with water to create a solution.

- Dosing System: Injects the pectin solution into the fruit mixture in a controlled manner.

- Filling and Packaging Equipment

- Filling Machine: Fills jars or containers with the hot jam.

- Capping Machine: Seals the jars or containers.

- Cooling and Labeling Equipment

- Cooling Conveyor: Cools down the filled jars.

- Labeling Machine: Applies labels to the jars.

- Cleaning and Sanitizing Equipment

- Cleaning-in-Place (CIP) System: Cleans the processing equipment without disassembly.

At We Smart Engineering, we go beyond providing equipment; we offer turnkey solutions that encompass design, installation, and ongoing support. Our commitment to innovation and quality empowers dairy businesses to thrive in a competitive market. Trust us as your partner in achieving operational excellence and delivering top-notch Jam products to consumers worldwide.